Understanding Diamond Mesh Sheet Metal

Definition and Overview

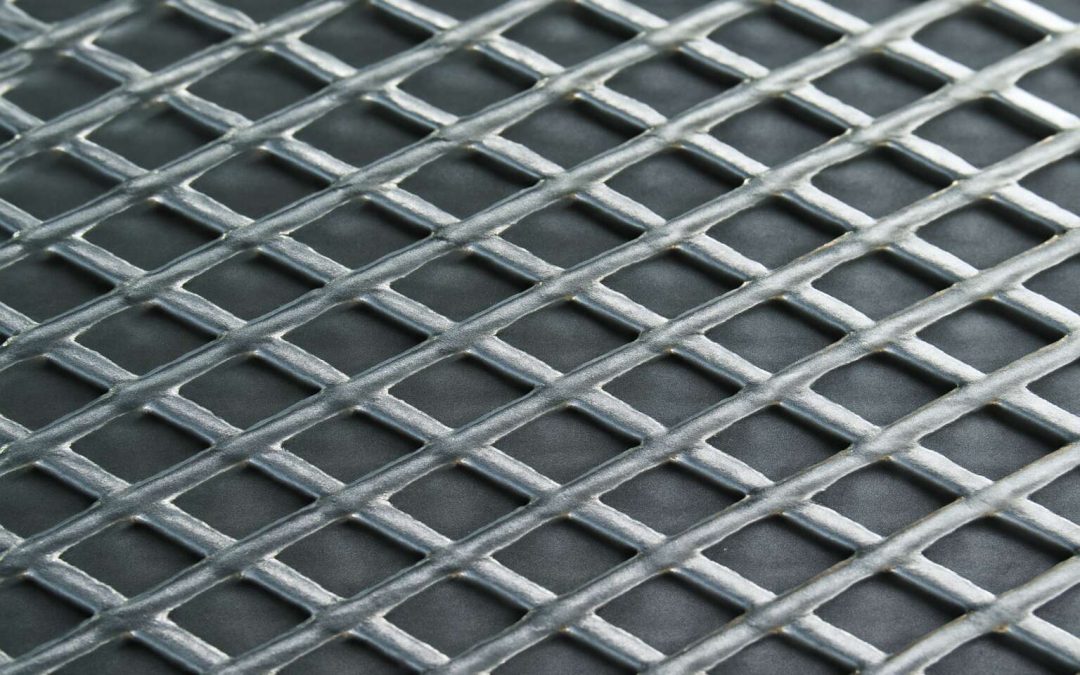

When it comes to versatile materials that blend durability with aesthetic appeal, few can match the charm of diamond mesh sheet metal. This innovative product, distinguished by its distinctive diamond-shaped openings, offers an optimal balance of strength and ventilation. Its unique pattern not only enhances structural integrity but also provides excellent airflow—an attribute highly prized in South Africa’s climate-conscious construction projects.

Understanding diamond mesh sheet metal begins with recognizing its primary function: a protective yet transparent barrier. Its robust construction makes it ideal for applications ranging from security fencing to decorative panels. The defining feature lies in the interlocking diamond pattern, which ensures resilience without sacrificing visibility. For those considering its use, here are some notable qualities:

- Corrosion resistance, vital for South Africa’s coastal regions

- Lightweight yet strong, simplifying installation

- Easy to customize for specific design needs

Ultimately, diamond mesh sheet metal exemplifies a harmonious blend of form and function, making it a staple in the modern South African landscape. Its adaptability and enduring strength continue to make it a favored choice among architects and builders alike.

Common Materials Used

When it comes to selecting the right material for diamond mesh sheet metal, understanding the common options is essential. These materials are chosen not only for their durability but also for their ability to withstand South Africa’s varied climate. Steel remains the most popular choice, especially galvanized steel, which offers excellent corrosion resistance—crucial for coastal regions where salt can accelerate rusting. Aluminum is another favored material, known for its lightweight nature and natural resistance to corrosion, making it ideal for decorative or architectural applications.

In addition to these, stainless steel is often used in environments demanding superior strength and longevity. Its resistance to staining and rust ensures that the diamond mesh sheet metal maintains its integrity over time. For specific projects, some manufacturers incorporate coatings or treat the metal to enhance durability further.

Here’s a quick overview of common materials used:

- Galvanized steel: Affordable, corrosion-resistant, and sturdy

- Aluminum: Lightweight, easy to work with, naturally resistant to corrosion

- Stainless steel: High strength, excellent longevity, resistant to staining

Manufacturing Processes

Manufacturing diamond mesh sheet metal involves precise processes that ensure durability and consistent quality. The most common method is cold rolling, where metal strips are shaped into a mesh pattern under high pressure. This technique allows for tight control over the diamond shape and size, which is crucial for applications requiring strength and uniformity.

Once shaped, the sheets often undergo additional treatments to enhance corrosion resistance. For example, galvanization involves coating the metal with zinc, creating a protective barrier against rust—especially important in South Africa’s coastal regions. Some manufacturers also employ laser cutting or punching, which offers high accuracy and clean edges for complex designs.

Understanding these manufacturing processes highlights why diamond mesh sheet metal is a versatile choice for fencing, architectural features, and filtration. The combination of advanced techniques and material selection ensures that each sheet meets the demands of diverse environments and uses.

Types of Diamond Mesh Sheets

When it comes to diamond mesh sheet metal, variety is the spice of life—and the key to unlocking its full potential. From the classic welded type to more intricate laser-cut designs, there’s a version suited for every need, whether it’s for fencing, architectural accents, or industrial filtration. These types of diamond mesh sheets are distinguished not only by their pattern but also by their manufacturing techniques and material composition.

Sturdy and adaptable, the most common types include welded diamond mesh sheets, which are perfect for structural applications, and expanded diamond mesh sheets, known for their lightweight yet durable nature. For those seeking precision and aesthetic finesse, laser-cut diamond mesh sheets offer intricate patterns with razor-sharp edges—ideal for modern architectural features. Additionally, galvanised options provide excellent corrosion resistance, making them suitable for South Africa’s coastal environments. Understanding these types helps in selecting the right diamond mesh sheet metal—because not all meshes are created equal, and your project deserves the best fit.

Applications and Uses of Diamond Mesh Sheet Metal

Industrial Applications

In the shadowed corridors of industry, where strength and resilience are often veiled in darkness, diamond mesh sheet metal emerges as a silent sentinel. Its intricate latticework, forged from the cold heart of steel or aluminum, whispers tales of durability and security. This versatile material finds its purpose in settings where both visibility and ventilation are paramount—allowing light to pierce through while safeguarding against the unseen threats lurking beyond.

Applications of diamond mesh sheet metal stretch far beyond mere protection. It is the backbone of industrial fencing, offering an unyielding barrier against intruders, yet permitting airflow that prevents suffocation of the workspace. In architectural realms, it lends an ominous yet captivating aesthetic, transforming mundane facades into hauntingly beautiful structures. For the industrial worker, it provides safety screens that shield from the chaos of moving machinery, all the while maintaining a ghostly transparency.

Intriguingly, the uses extend into the realm of filtration and reinforcement, making it an indispensable element in the construction of machinery and storage units. Its ability to withstand the relentless assault of time and elements makes diamond mesh sheet metal a staple in South Africa’s rugged terrains—where resilience isn’t just preferred, but vital.

Architectural and Design Uses

In the world of architecture and design, the allure of diamond mesh sheet metal extends far beyond its utilitarian origins. Its distinctive geometric pattern, forged from resilient steel or aluminum, breathes life into facades and interiors, transforming mundane surfaces into captivating visual narratives. The interplay of light and shadow through the open lattice invites a sense of mystery and depth, making it an ideal choice for artistic architectural expressions.

From decorative screens to intricate façade cladding, diamond mesh sheet metal lends a modern, edgy aesthetic that captivates the eye. Its versatility is showcased in applications such as sunshades, balustrades, and even ceiling panels, where durability meets avant-garde appeal. For designers seeking to marry function with form, this material offers an unparalleled canvas, enabling the creation of spaces that are both resilient and visually stunning.

Moreover, the adaptability of diamond mesh sheet metal means it can be customized for specific structural needs. Whether woven into complex geometric patterns or left in its classic form, it serves as a testament to craftsmanship and innovation. This material isn’t just about aesthetics—it’s about engineering resilience, making it a vital component in South Africa’s architectural landscape, where strength and style must coexist seamlessly.

Security and Safety Solutions

When it comes to bolstering security without sacrificing style, diamond mesh sheet metal proves to be a formidable ally. Its robust steel or aluminum construction acts as a silent guardian, deterring intruders while maintaining a sleek, contemporary look. Whether guarding commercial properties or residential spaces, this material’s open lattice design allows for visibility and airflow—crucial elements often overlooked in security planning.

In high-traffic areas, diamond mesh sheet metal is often woven into resilient security screens, fencing, and even window guards. Its durability makes it resistant to tampering and vandalism, giving peace of mind in environments where safety is paramount. Plus, its versatile nature means it can be customized into various sizes and patterns to fit specific security needs, blending seamlessly into the aesthetic of any structure.

For added security, consider these common applications:

- Perimeter fencing that combines strength with style

- Protective barriers for machinery and industrial zones

- Reinforced enclosures for valuable assets

Diamond mesh sheet metal isn’t just about keeping unwanted visitors out; it’s about creating a resilient barrier that stands the test of time. Its adaptive, high-security applications make it an indispensable element in South Africa’s landscape of protective solutions—where safety and durability are non-negotiable. Truly, it’s the unsung hero in the world of security and safety solutions that quietly works behind the scenes, ensuring everything stays where it belongs—inside, safe and sound.

Agricultural and Landscaping Uses

In the vast landscape of South Africa’s agricultural and landscaping pursuits, resilience and adaptability are not just virtues—they are necessities. Diamond mesh sheet metal emerges as an unsung hero in this realm, offering more than just security; it provides a canvas for innovation rooted in practicality and durability. Its open lattice design allows for optimal airflow and sunlight penetration, making it ideal for protecting crops, livestock, and landscaped spaces without creating a fortress of isolation.

Farmers and landscapers frequently harness the versatility of diamond mesh sheet metal for a variety of applications. It’s commonly used in fencing systems that need to withstand the harsh African climate while ensuring animals stay contained and safe. The material’s toughness resists corrosion, tampering, and the wear-and-tear of outdoor environments, making it an enduring choice for long-term projects. Whether as boundary fencing, garden enclosures, or even protective screens for nursery plants, this metal strikes a perfect balance between form and function.

In regions where water conservation and sustainable practices are paramount, diamond mesh sheet metal also plays a crucial role. Its design allows for natural pest control, airflow, and drainage, reducing reliance on chemical treatments and artificial barriers. This eco-conscious approach aligns seamlessly with South Africa’s agricultural ethos, emphasizing harmony with nature while safeguarding resources.

For those seeking a resilient, adaptable solution, the applications of diamond mesh sheet metal extend beyond the obvious. Its ability to be customized into various sizes and patterns means it can be precisely tailored for specific landscaping needs—be it protecting delicate plantings or creating durable partitions. The material’s strength and flexibility foster a new level of creative expression in outdoor design, where safety and aesthetics are no longer mutually exclusive.

Benefits of Choosing Diamond Mesh Sheet Metal

Durability and Strength

When considering the robustness of construction materials, durability and strength often emerge as paramount qualities. Diamond mesh sheet metal exemplifies these traits remarkably well, offering a resilient solution that withstands the test of time. Its unique pattern not only enhances structural integrity but also distributes stress evenly, reducing the risk of failure under heavy loads. This makes it an ideal choice for demanding environments where longevity is non-negotiable.

Beyond raw strength, diamond mesh sheet metal boasts an impressive resistance to corrosion and weathering, especially when manufactured from stainless steel or galvanized materials. This resilience ensures that installations remain pristine and functional, even amidst South Africa’s diverse climate challenges. Its robustness makes it suitable for a wide range of applications, from industrial fencing to architectural accents, where durability directly correlates with safety and performance.

In essence, choosing diamond mesh sheet metal is an investment in enduring quality. Its capacity to combine strength with adaptability sustains its reputation as a versatile material, vital for projects that demand longevity and resilience in a dynamic environment.

Ventilation and Airflow

When it comes to ventilation and airflow, few materials strike the perfect balance between functionality and finesse quite like diamond mesh sheet metal. Its open, geometric pattern facilitates optimal air circulation, making it an ideal choice for environments where breathability is paramount. Whether used in industrial exhaust systems or architectural facades, this sheet metal ensures fresh air flows freely while maintaining a sleek aesthetic.

The beauty of diamond mesh sheet metal lies not just in its visual appeal but in its practical benefits. Its design allows for excellent drainage and air exchange, preventing moisture buildup and reducing the risk of corrosion over time. This resilience is particularly crucial in South Africa’s diverse climate, where unpredictable weather patterns challenge even the most robust materials.

Furthermore, selecting diamond mesh sheet metal offers a nuanced advantage: it provides security without sacrificing ventilation. For instance, in security fencing applications, its sturdy yet breathable structure deters trespassers while allowing for continuous airflow. This harmony of safety and practicality underscores why this versatile material remains a top pick in various sectors.

- Enhanced airflow promotes healthier environments, especially in industrial or agricultural settings.

- Corrosion-resistant qualities extend the lifespan of installations, reducing maintenance costs.

- The open pattern ensures efficient drainage, preventing water accumulation and potential damage.

Ultimately, the benefits of choosing diamond mesh sheet metal extend beyond mere aesthetics. Its unique combination of durability, airflow management, and security makes it a compelling choice for projects demanding both resilience and functionality in South Africa’s challenging climate.

Aesthetic Appeal

In the shadowed corridors of urban innovation and rugged wilderness alike, the allure of diamond mesh sheet metal whispers of resilience and understated elegance. Its striking geometric pattern transforms functional security into a canvas of artistic expression, where practicality meets aesthetic finesse. This material does not merely serve a purpose; it elevates the very environment it adorns, casting an air of refined strength that commands attention.

The beauty of diamond mesh sheet metal extends beyond its visual charm. It embodies a harmonious balance—allowing light and air to dance through its open lattice while maintaining an unyielding stance against the elements. Its versatile design lends itself seamlessly to creating striking architectural facades or discreet security enclosures, where form and function intertwine without compromise.

- Enhanced visual appeal that elevates architectural landscapes

- Seamless integration into design schemes that demand both beauty and strength

- A symbol of resilience, standing firm against South Africa’s unpredictable climate

In every twisted wire and every open diamond, there lies a story of durability and grace—an ode to the silent guardians of safety and style. Choosing diamond mesh sheet metal is not merely a matter of preference but an affirmation of enduring artistry in a world that often favors the ephemeral. Its dark allure beckons those who seek beauty woven with unbreakable resolve, whispering promises of longevity and refined distinction amidst the chaos of modern life.

Cost-Effectiveness

In a landscape where durability often comes at a steep price, choosing diamond mesh sheet metal offers an unexpected twist—cost-effectiveness wrapped in resilience. The intrinsic strength of this material means fewer replacements and repairs over time, translating into significant savings—an advantage that cannot be overlooked in South Africa’s unpredictable climate. Its versatile nature allows it to serve multiple purposes, from protective fencing to decorative facades, without the need for costly modifications or additional reinforcements.

Moreover, the manufacturing process of diamond mesh sheet metal optimizes material usage, reducing waste and lowering overall costs. This efficiency makes it an appealing choice for large-scale projects and budget-conscious builders alike. To highlight its economic appeal, consider these benefits:

- Long-lasting performance minimizes maintenance expenses

- Reduced material waste ensures affordability

- Multi-purpose application reduces the need for multiple materials

Every coil of diamond mesh sheet metal whispers promises of endurance and value, making it a wise investment for those who refuse to compromise between beauty, strength, and fiscal prudence. Its cost-effectiveness is not merely a benefit but a testament to its role as a silent yet steadfast guardian of both style and savings.

Factors to Consider When Purchasing Diamond Mesh Sheet Metal

Material Compatibility

When selecting diamond mesh sheet metal, understanding material compatibility is crucial—yet often overlooked. The wrong choice can compromise strength, safety, and longevity, especially in demanding environments. In South Africa’s diverse industries, from construction to security, choosing the right material ensures performance that stands the test of time.

Factors such as exposure to corrosive elements, weight requirements, and thermal conditions all influence the ideal material. For instance, stainless steel offers excellent corrosion resistance, making it perfect for outdoor or humid settings, while aluminum provides lightweight durability.

To simplify decision-making, consider these key points:

- Environmental conditions and exposure to elements

- Mechanical stress and load-bearing requirements

- Compatibility with existing infrastructure or protective coatings

Matching the right diamond mesh sheet metal with your specific needs can be the difference between a fleeting solution and a game-changing investment.

Gauge and Thickness

Choosing the right gauge and thickness for your diamond mesh sheet metal is more than a matter of preference; it’s an existential decision that can determine the longevity and resilience of your project. In South Africa’s diverse environments, where corrosion and mechanical stress are constant companions, understanding the nuances of material strength becomes paramount. A thinner gauge might seem economical, but it could compromise structural integrity under heavy loads or harsh conditions.

When selecting diamond mesh sheet metal, consider the specific application’s demands. For example, security fencing requires a thicker gauge for durability, while decorative purposes might benefit from a lighter gauge that offers elegance without sacrificing strength. To aid your decision, evaluate factors such as:

- The expected mechanical stress and load-bearing capacity

- The environmental exposure—whether it’s humid coastal air or dusty inland conditions

- Compatibility with existing infrastructure or protective coatings that might influence gauge choice

Understanding these elements ensures your investment in diamond mesh sheet metal delivers performance that endures far beyond the initial installation—transforming a simple component into a testament of resilience.

Mesh Size and Pattern

Choosing the right diamond mesh sheet metal isn’t just about size; it’s about understanding how the pattern and mesh size influence functionality and visual appeal. In South Africa’s diverse environments, the pattern can determine airflow, security, and aesthetic impact. A tighter pattern offers enhanced security and durability, while a broader diamond mesh sheet metal allows for better ventilation and an airy look.

When selecting mesh size, consider the intended purpose. For example, a smaller diamond pattern might deter intruders more effectively, making it ideal for security applications. Conversely, larger openings are perfect for decorative facades or agricultural fencing where airflow is essential. To make an informed decision, evaluate:

- The level of security or airflow required

- The visual impact and design preferences

- The environmental factors influencing wear and tear

Understanding these factors ensures your investment in diamond mesh sheet metal aligns perfectly with your project’s demands, transforming practicality into resilience and style.

Finish and Coatings

When choosing the finish and coatings for diamond mesh sheet metal, one must consider not just appearance but resilience—an armor that withstands South Africa’s diverse climate and challenging environment. The right coating can transform ordinary metal into an enduring sentinel against corrosion, rust, and wear. Whether you seek a sleek, polished look or a rugged, textured finish, the coating must align with the specific demands of your project.

In environments where exposure to moisture and UV rays is relentless, a high-quality galvanizing or powder coating becomes indispensable. These protective layers act as a shield, extending the lifespan of your diamond mesh sheet metal and maintaining its visual appeal over time. For aesthetic finesse, color finishes and specialized coatings can provide a vibrant, modern touch while safeguarding against the elements.

Furthermore, evaluating the compatibility of the coating with your chosen material ensures seamless adhesion and long-term performance. A thoughtful selection process—considering factors like environmental conditions and desired aesthetic—can elevate your investment from mere functionality to a statement of resilience and style. After all, in the realm of diamond mesh sheet metal, the finish is the cloak that preserves its strength and beauty through the ages.

Price and Supplier Selection

When investing in diamond mesh sheet metal, price is often the first factor that captures attention. Yet, beneath the surface of seemingly straightforward costs lies a complex web of considerations—each echoing the true value of your purchase. In South Africa’s fluctuating market, understanding the nuances of pricing and supplier reliability can mean the difference between enduring resilience and fleeting utility.

Choosing the right supplier involves more than just comparing quotes. It requires assessing the authenticity of the materials, the supplier’s reputation, and their capacity to meet your project’s specific demands. Look for suppliers who offer transparent pricing structures and guarantees on quality. An experienced supplier will also provide insights into the manufacturing process and material origins, ensuring your diamond mesh sheet metal performs under the harshest conditions.

To streamline your decision-making, consider these factors:

- Material quality and grade

- Pricing consistency and transparency

- Supplier reputation and customer reviews

- Delivery timelines and flexibility

Remember, in the realm of diamond mesh sheet metal, the true value is rooted in durability and reliability. A slightly higher initial investment can often translate into long-term savings, especially when paired with a trusted supplier committed to excellence. The choice of price and supplier isn’t merely transactional—it’s a moral decision to uphold quality, resilience, and integrity in every application.

Installation and Maintenance of Diamond Mesh Sheet Metal

Installation Techniques

Installing diamond mesh sheet metal is an art that marries precision with purpose. In South Africa’s rugged landscape, where resilience is paramount, the proper technique ensures longevity and optimal performance. The process begins with meticulous measurement—every cut and bend must align seamlessly, transforming raw material into a fortress of strength. Secure fastening is crucial, often employing rivets, screws, or welds, to withstand the relentless forces of nature and time.

Once in place, maintenance becomes an ongoing dance of care and inspection. Regularly check for signs of corrosion or damage, especially in coastal or industrial environments where exposure to moisture and pollutants can accelerate deterioration. Applying protective coatings or paint—specifically designed for diamond mesh sheet metal—can significantly prolong its lifespan. A simple, yet effective, maintenance routine keeps the mesh resilient, sturdy, and visually appealing for years to come.

Maintenance Tips

Installing diamond mesh sheet metal is a delicate dance between craftsmanship and resilience. In South Africa’s diverse climate, where coastal humidity and inland dryness challenge even the sturdiest materials, proper installation ensures lasting performance. Precision in measurement and cutting is vital—each bend must align perfectly to preserve the integrity of the mesh’s pattern and strength.

Secure fastening is equally critical. Using high-quality rivets, screws, or welds, installers create a formidable barrier against the relentless forces of nature. Once in place, routine maintenance is key to safeguarding its longevity. Inspect for signs of corrosion or damage, especially in environments prone to moisture or industrial pollutants. Applying protective coatings designed specifically for diamond mesh sheet metal forms a shield that prolongs its life and maintains its aesthetic appeal.

To streamline upkeep, consider these essential tips:

- Regularly clean the surface with gentle detergents to prevent buildup.

- Touch up any areas showing signs of rust or corrosion promptly.

- Use compatible protective coatings to enhance resistance to environmental elements.

Adopting a consistent inspection routine transforms maintenance into a seamless part of the overall durability of your diamond mesh sheet metal installations. Such care not only preserves functionality but also elevates visual appeal, reinforcing its role as a versatile solution in South Africa’s dynamic landscape.

Troubleshooting Common Issues

In the intricate dance of installation and ongoing maintenance, the resilience of diamond mesh sheet metal is truly tested by South Africa’s unpredictable climate. When properly secured—whether through welding, rivets, or high-grade screws—this material transforms into a formidable barrier against harsh environmental forces. Yet, even the most robust installations are susceptible to the subtle encroachments of corrosion or mechanical wear over time.

Common issues such as rust, warping, or detachment often stem from inadequate fastening or neglect. Troubleshooting these problems involves meticulous inspection: look for signs of deterioration, especially in moist coastal regions or industrial zones. Applying compatible protective coatings can dramatically reduce the risk of corrosion, restoring both durability and aesthetic appeal. For those facing persistent issues, re-evaluating the gauge or mesh pattern might be necessary to ensure optimal strength and airflow, especially in applications demanding both security and ventilation.

- Ensure fasteners remain tight and free of debris.

- Regularly clean the surface with gentle detergents to prevent buildup.

- Promptly address signs of rust, applying protective coatings for added resistance.

Understanding the nuances of installation and maintenance for diamond mesh sheet metal not only prolongs its functional lifespan but also preserves its visual integrity amidst South Africa’s climate complexities. When issues arise, proactive troubleshooting—rooted in careful inspection and timely intervention—becomes essential to uphold its enduring strength and versatility.

Choosing the Right Supplier for Diamond Mesh Sheet Metal

Quality Assurance and Certifications

In the shadowed corridors of industry, where strength and reliability are the only truths, choosing the right supplier for diamond mesh sheet metal becomes a matter of dark necessity. A reputable provider does more than just deliver; they forge a covenant of quality assurance and unwavering standards. When the metallic lattice is destined to guard secrets or uphold the fragile veneer of aesthetics, only the most certified suppliers will suffice.

Look for suppliers that hold industry certifications such as ISO 9001, which whispers promises of meticulous quality management. Trust is cemented through transparent documentation—material certifications, test reports, and adherence to international standards are the silent guardians of integrity. To navigate this treacherous landscape, consider these key factors:

- Consistent quality control processes

- Proven track record of supplying durable diamond mesh sheet metal

- Availability of comprehensive certifications and material traceability

In a realm where every detail matters, aligning with a supplier that values precision and authenticity ensures the longevity of your project—an investment in darkness that endures beyond the fleeting light of compromise.

Customization Options

Choosing the right supplier for diamond mesh sheet metal isn’t just about price or availability; it’s about forging a partnership rooted in trust and precision. In South Africa’s dynamic markets, where construction, security, and aesthetic projects demand unwavering quality, the supplier’s ability to customize options becomes paramount. Tailored solutions—such as specific mesh sizes, coatings, or gauge variations—can significantly influence the success of your project.

Look for suppliers that offer comprehensive customization options, including:

- Different mesh patterns and sizes to match your unique requirements

- Specialized finishes or coatings for enhanced durability or aesthetic appeal

- Flexible gauge and thickness selections to balance strength with cost

This level of customization underscores a supplier’s commitment to meeting precise needs, ensuring your diamond mesh sheet metal aligns perfectly with your vision. When selecting a partner, consider their ability to provide clear documentation of customization capabilities and open channels for bespoke requests. After all, in a landscape where every detail shapes the outcome, working with a supplier that values adaptability and craftsmanship can transform your project from ordinary to extraordinary.

Lead Times and Shipping

When selecting a supplier for diamond mesh sheet metal, understanding lead times and shipping logistics can make or break your project timeline. In South Africa’s vibrant markets, where efficiency is crucial, a supplier’s ability to deliver promptly ensures your work stays on track. Fast and reliable shipping not only reduces downtime but also demonstrates the supplier’s commitment to customer satisfaction.

It’s essential to inquire about the supplier’s typical lead times for custom orders, especially when specific mesh sizes or coatings are required. Some suppliers offer expedited processing, which can be a game-changer for tight schedules. Additionally, clear communication regarding shipping options—whether by land, sea, or air—helps you plan effectively. For peace of mind, look for suppliers that provide tracking and transparent delivery estimates, ensuring your diamond mesh sheet metal arrives precisely when needed.

- Assess the supplier’s reputation for punctuality and reliability.

- Choose a partner with flexible shipping options tailored to South Africa’s unique logistics landscape.

- Ensure they offer comprehensive documentation for order tracking and delivery timelines.

By prioritizing these aspects, you can seamlessly integrate diamond mesh sheet metal into your project without unexpected delays, turning complex logistics into a smooth, almost magical process!

Customer Support and Services

Choosing the right supplier for diamond mesh sheet metal can significantly impact your project’s success. Reliable customer support and comprehensive services ensure you’re not left in the dark when questions or issues arise. A good supplier offers clear communication channels, quick response times, and expert advice tailored to South Africa’s unique market needs. This level of support can streamline your procurement process and prevent costly delays.

Furthermore, an ideal supplier provides added-value services such as technical consultations, custom fabrication options, and flexible order quantities. These services demonstrate a commitment to customer satisfaction and help you adapt the diamond mesh sheet metal to your specific application. In South Africa’s fast-paced markets, partnering with a supplier that prioritizes after-sales support can turn an ordinary transaction into a dependable, long-term relationship.

When assessing potential suppliers, consider their reputation for responsiveness and transparency. It’s advantageous to select a company that offers a variety of shipping options and maintains open lines of communication about order status. This ensures your diamond mesh sheet metal arrives on time, ready to meet your project demands.