Understanding Diamond Mesh Steel

Overview of Diamond Mesh Steel

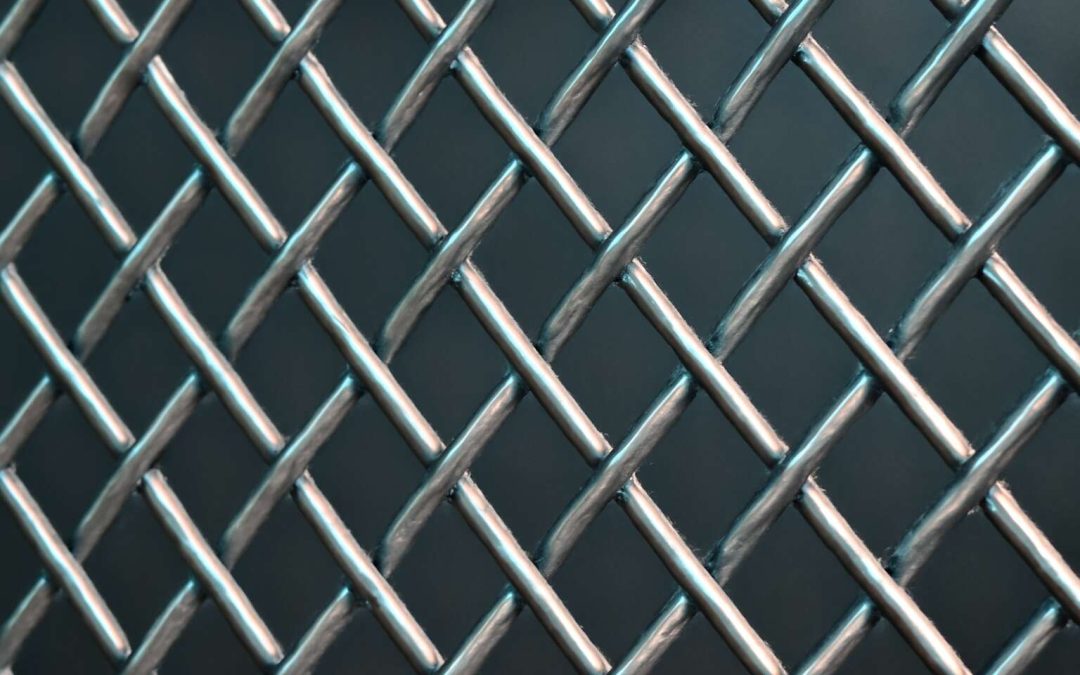

Diamond mesh steel stands as a testament to modern engineering ingenuity, offering a resilient yet flexible solution for a wide array of construction and industrial applications. Its distinctive diamond-shaped pattern isn’t just for aesthetics — it plays a vital role in enhancing strength and durability. With the ability to withstand harsh environmental conditions, this versatile material has become a staple in securing safety barriers, fencing, and even architectural designs.

What sets diamond mesh steel apart is its unique configuration, which distributes load evenly across its surface. This makes it especially effective in demanding environments where structural integrity is paramount. Here are some key advantages of diamond mesh steel:

- Exceptional tensile strength, resisting deformation under pressure

- Corrosion resistance, suitable for outdoor and coastal projects

- Ease of installation due to its flexible yet sturdy nature

Understanding the intricacies of diamond mesh steel reveals why it continues to be a preferred choice across industries. Its blend of strength, flexibility, and longevity makes it a true engineering marvel, capable of transforming ordinary structures into resilient masterpieces.

Characteristics and Benefits

Diamond mesh steel is a marvel of modern metallurgy, combining strength and resilience in a form that seems almost enchanted. Its characteristic diamond-shaped pattern isn’t merely an aesthetic choice; it’s a strategic design that distributes load evenly across the surface, making it extraordinarily effective in demanding environments. This unique configuration ensures that the material can resist deformation and maintain its integrity under pressure, a testament to its exceptional tensile strength.

One of the most compelling benefits of diamond mesh steel is its corrosion resistance. This quality renders it suitable for outdoor applications, including coastal projects where salt-laden air can accelerate deterioration. Its durability is further enhanced by the ability to withstand harsh weather conditions, ensuring longevity and minimal maintenance over time.

Flexibility is another standout feature. Despite its sturdy appearance, diamond mesh steel can be easily manipulated and installed, allowing it to adapt seamlessly to various structural forms. Whether used in securing safety barriers or architectural accents, this versatile material seamlessly marries form with function. Its resilient nature transforms ordinary frameworks into bastions of durability and safety, echoing the mastery of advanced engineering.

Common Applications and Uses

Diamond mesh steel has become an indispensable component across a spectrum of demanding industries, thanks to its unparalleled strength and durability. Its versatility makes it a favourite choice for projects that require both security and resilience. From safeguarding premises to supporting architectural structures, this material’s unique properties are harnessed in ways that often transcend expectations.

One of the most intriguing applications of diamond mesh steel lies in the realm of safety barriers and fencing. Its robust construction deters intrusion while allowing visibility, making it ideal for perimeter security around critical infrastructure. Additionally, its corrosion resistance ensures these barriers withstand the elements, especially in coastal or harsh environments.

Architects and engineers also utilise diamond mesh steel extensively in construction and decorative features. Its flexible nature allows it to be shaped into intricate forms or used as reinforcement within concrete. For example, in civil engineering projects, it provides reinforcement for roads and pavements, maintaining integrity under heavy loads.

- Industrial fencing and security enclosures

- Structural reinforcement in concrete applications

- Architectural accents and decorative panels

- Protective barriers in hazardous environments

In each of these applications, diamond mesh steel’s ability to combine resilience with adaptability elevates it from mere material to strategic asset. Its widespread use underscores a silent promise: durability that endures, no matter the challenge.

Types of Diamond Mesh Steel

Different Types by Material – Galvanized, Stainless Steel, Powder-Coated

When it comes to selecting the right diamond mesh steel for your project, understanding the different material options is essential. Each type offers unique properties tailored to specific environments and demands. Galvanized diamond mesh steel, for instance, is renowned for its exceptional corrosion resistance, making it ideal for outdoor fencing and agricultural applications. Its zinc coating forms a durable barrier that withstands the elements with minimal maintenance.

On the other hand, stainless steel diamond mesh steel provides superior strength and a sleek, corrosion-resistant surface suitable for environments where hygiene and longevity are paramount. This material is often preferred in food processing plants and cleanroom facilities, where contamination must be kept at bay. Powder-coated diamond mesh steel, with its customised colour options and added protection against chipping, offers versatility and aesthetic appeal without compromising durability.

Choosing the right type of diamond mesh steel hinges on understanding these material distinctions. Whether galvanised for rugged outdoor use, stainless steel for high-performance indoor applications, or powder-coated for visual appeal, each variant ensures that the steel mesh serves its purpose efficiently and effectively. The diversity in material composition underscores just how adaptable and vital diamond mesh steel truly is in modern industrial and commercial settings.

Variations in Mesh Size and Pattern – Standard, Heavy-Duty, Custom Designs

When it comes to diamond mesh steel, size and pattern variations can make all the difference between a project that’s functional and one that’s a feast for the eyes. Surprisingly, the choice of mesh pattern isn’t just about aesthetics — it influences strength, flexibility, and even the ease of installation. With options ranging from standard to heavy-duty, each variation caters to a specific need, ensuring your project’s durability and performance.

The standard diamond mesh steel is the go-to for most applications. It strikes a perfect balance between mesh size and strength, making it suitable for fencing, animal enclosures, or even decorative purposes. But if you’re tackling something that demands extra resilience—think industrial security or heavy machinery barriers—then heavy-duty versions come into play. These feature tighter, more robust patterns that can withstand significant stress.

Of course, custom designs are where things get interesting. For specialised projects, tailored mesh sizes and unique patterns can be created, offering the ultimate in bespoke flexibility. Whether you need larger diamond shapes for visibility or smaller, more intricate patterns for a refined look, the possibilities are almost endless. After all, when it comes to diamond mesh steel, variety truly is the spice of life.

Specs and Standards – Industry Certification and Quality Benchmarks

When it comes to diamond mesh steel, adherence to industry specifications is not merely a bureaucratic formality; it’s the bedrock of quality and safety. Specifications such as ASTM A392 for galvanised steel or ASTM A240 for stainless steel set rigorous benchmarks that manufacturers strive to meet. These standards ensure the mesh’s durability, corrosion resistance, and overall performance across applications. Moreover, certifications from recognised bodies like ISO or Lloyd’s Register serve as a testament to a product’s compliance with international quality benchmarks. Such credentials are not just badges of honour—they’re vital for projects demanding the highest levels of integrity.

For those seeking precision, understanding the specific standards governing the various types of diamond mesh steel is essential. The following highlights some key specifications:

- Material composition and tensile strength requirements

- Mesh size and pattern tolerances

- Corrosion resistance criteria for galvanised and stainless steel variants

- Welding and fabrication standards to ensure structural integrity

By selecting diamond mesh steel that adheres to recognised standards, architects and engineers can rest assured that their projects will stand the test of time, resisting both the elements and the wear and tear of daily life. After all, in the realm of steel mesh, compliance isn’t just a box to check—it’s the foundation of trust and excellence.

Advantages of Using Diamond Mesh Steel

Enhanced Durability and Strength

In a world where resilience is often the silent hero, diamond mesh steel stands as a testament to enduring strength and unwavering durability. Its intricate pattern, forged from high-quality steel, transforms strength into artistry—each interwoven strand a metaphor for resilience against the relentless march of time and wear. This material’s enhanced durability is not merely a boast but a tangible reality; it resists corrosion, impacts, and fatigue, making it ideal for demanding environments.

What truly elevates diamond mesh steel beyond its aesthetic appeal is its capacity to withstand the harshest conditions without compromising structural integrity. For applications where safety and longevity are paramount, this material offers a formidable advantage. Its tensile strength ensures that structures remain steadfast under pressure, while its corrosion resistance prolongs service life—an investment in stability that pays dividends over decades.

- Superior impact resistance

- Long-lasting corrosion protection

- Enhanced tensile and structural strength

In essence, choosing diamond mesh steel is embracing a material that embodies both beauty and brawn—an unyielding guardian in every project it adorns. Its robust nature transforms ordinary constructions into resilient fortresses, standing tall through the ages with grace and grit.

Corrosion Resistance Features

In a realm where decay often lurks just beyond the shadows, the virtue of corrosion resistance becomes an unspoken guardian. Diamond mesh steel, with its dark, shimmering lattice, stands as a testament to resilience that defies the relentless assault of time and elements. Its innate ability to withstand moisture, salt, and corrosive environments elevates it far beyond mere aesthetics, transforming it into a stalwart protector of structural integrity.

This formidable material offers a host of advantages, chief among them being its exceptional resistance to corrosion. Unlike ordinary steel that succumbs to rust and deterioration, diamond mesh steel maintains its integrity even in the most hostile climates. Its protective coating or alloy composition acts as an invisible shield, ensuring longevity and reducing maintenance costs. For those seeking enduring strength, the corrosion resistance of diamond mesh steel is an invaluable asset—preserving safety and stability through decades of exposure.

- Enhanced longevity in harsh environments

- Reduced maintenance and replacement costs

- Preservation of structural strength over time

In the shadowy corridors of construction and industrial applications, diamond mesh steel’s corrosion resistance whispers promises of durability. Its capacity to endure the corrosive whispers of saltwater and chemical exposure makes it the dark knight of materials—steadfast and unwavering, even when the world around it chips away. Truly, this material embodies a rare fusion of resilience and beauty, an armour forged for eternity’s silent watch.

Ease of Installation and Maintenance

In the realm of construction and industrial innovation, the ease with which a material can be installed and maintained often determines its true worth. Diamond mesh steel emerges not only as a symbol of resilience but also as an exemplar of straightforwardness—its design simplicity streamlining the journey from raw material to finished masterpiece. The lightweight yet sturdy lattice structure allows for quick handling, reducing labour time and enhancing project efficiency.

Furthermore, the maintenance of diamond mesh steel is remarkably uncomplicated. Its inherent corrosion resistance means that routine upkeep remains minimal, allowing the material to retain its formidable strength without frequent intervention. This durability translates into significant long-term savings and fewer disruptions, offering peace of mind to engineers and facility managers alike.

For those seeking swift, secure, and enduring solutions, the advantages of using diamond mesh steel are clear. Its combination of ease of installation and low-maintenance demands makes it an invaluable asset—transforming complex challenges into seamless operations. Truly, this material’s adaptability ensures that durability and beauty are never mutually exclusive, but instead, harmoniously intertwined in every application.

Aesthetic and Design Flexibility

Diamond mesh steel offers a unique blend of aesthetic appeal and versatile design options. Its open, geometric pattern provides a modern look that enhances the visual impact of any project. Whether used in architectural facades, security fencing, or decorative screens, the intricate diamond pattern captures attention and adds sophistication.

One of the key advantages of using diamond mesh steel is its adaptability. The material can be customised to fit various design specifications, allowing for seamless integration into both functional and artistic applications. Different mesh sizes and patterns—such as standard, heavy-duty, or bespoke designs—offer flexibility to meet specific project requirements.

In addition to its visual qualities, diamond mesh steel can be combined with various finishes and colours, further expanding its design potential. This versatility makes it an ideal choice for architects and designers seeking durable, attractive solutions that do not compromise on strength or longevity.

Manufacturing and Quality Assurance

Production Processes – Welding, Weaving, Coating Techniques

Manufacturing high-quality diamond mesh steel involves a meticulous blend of advanced techniques and rigorous quality assurance protocols. Each step in the production process is designed to enhance the strength, durability, and precision of the finished product. Welding, for example, is performed using state-of-the-art methods that ensure seamless joints without compromising the integrity of the mesh pattern. This critical process guarantees that the diamond mesh steel retains its structural stability even under extreme conditions.

Weaving techniques also play a vital role—balancing flexibility with robustness. Skilled artisans employ specialised machinery to produce consistent diamond patterns, maintaining tight control over dimensions and spacing. The coating process, often involving galvanisation or powder-coating, adds an extra layer of corrosion resistance and aesthetic appeal, prolonging the lifespan of the diamond mesh steel in harsh environments.

To uphold the highest standards, manufacturers implement comprehensive quality assurance production processes. These include industry certification checks, tensile strength testing, and surface finish inspections, all aimed at delivering a product that meets or exceeds industry benchmarks. The integration of these techniques ensures that every piece of diamond mesh steel not only meets specifications but also withstands the test of time.

Quality Control Measures – Testing, Inspection, Certification

When it comes to manufacturing diamond mesh steel, precision isn’t just a bonus — it’s the backbone of every high-quality piece. Rigorous quality assurance measures ensure that each panel meets the demanding standards of strength, durability, and corrosion resistance that industry leaders expect. It’s no exaggeration to say that these checks are the gatekeepers of excellence, transforming raw materials into reliable, long-lasting structural assets.

To maintain impeccable standards, manufacturers employ a comprehensive array of quality control measures, including meticulous testing and inspection procedures. These may involve tensile strength tests to verify load-bearing capacity or surface finish assessments to guarantee aesthetic consistency. Industry certification checks act as the seal of approval, confirming that each batch of diamond mesh steel aligns with international benchmarks.

For added assurance, some producers utilise advanced certification frameworks like ISO or ASTM standards, ensuring the product’s integrity across various applications. This rigorous combination of testing, inspection, and certification ensures that the diamond mesh steel delivered to project sites is nothing short of exemplary — resilient, reliable, and ready to withstand the harshest conditions with a touch of steel-hard finesse.

Buying Guide for Diamond Mesh Steel

Factors to Consider – Gauge, Mesh Size, Material Type

Amidst the shadows of industrial innovation, choosing the right diamond mesh steel can feel like navigating a labyrinth of choice, where each factor whispers secrets of durability and strength. The weight of your decision hinges largely on three vital considerations: gauge, mesh size, and material type.

Gauging the thickness of your diamond mesh steel is akin to measuring the pulse of resilience—thinner gauges offer flexibility, while thicker gauges promise unwavering robustness. Mesh size, the intricate lattice pattern, influences everything from light filtration to security, making it a pivotal element in your selection. Meanwhile, the material type—be it galvanised, stainless steel, or powder-coated—imbues the steel with unique properties, from corrosion resistance to aesthetic allure.

For those seeking the perfect balance, understanding these factors becomes an act of craftsmanship, shaping the very fabric of your project. As you delve deeper into your quest for the ideal diamond mesh steel, remember: each detail, no matter how subtle, weaves into the larger story of strength and endurance.

How to Choose the Right Supplier – Reputation, Certifications, Customer Support

Choosing the right supplier for your diamond mesh steel is an act of trust, where reputation and reliability become your guiding stars. In a marketplace crowded with options, partnering with a provider known for unwavering integrity and consistent quality can turn a daunting task into a seamless journey. A supplier with a solid reputation often signals adherence to industry standards, ensuring your project’s foundation is built on a bedrock of excellence.

Certifications serve as the silent attestations of quality—ISO standards, industry-specific benchmarks, and rigorous testing procedures distinguish the reputable from the reckless. These benchmarks guarantee that the diamond mesh steel you acquire not only meets but exceeds expectations for durability and safety. Customer support, often overlooked, is the lighthouse in foggy waters; responsive, knowledgeable assistance transforms a transactional relationship into a trusted alliance.

- Evaluate the supplier’s industry reputation through reviews and client testimonials.

- Verify certifications and compliance with recognised standards.

- Assess the quality of customer support and after-sales service.

In the labyrinth of selection, these pillars of credibility and service become your compass, guiding you towards the optimal source for your diamond mesh steel needs—ensuring each piece woven into your project is a testament to excellence.

Pricing and Cost Factors – Quantity, Customization, Lead Times

The cost of diamond mesh steel can often feel like navigating a labyrinth—complex but rewarding when understood. Pricing varies significantly depending on several pivotal factors, each adding its own layer of value to the final investment. One key element is the quantity purchased; larger orders generally attract bulk discounts, making volume a powerful lever in cost management. Customisation options, such as specialised mesh patterns or specialised coatings, naturally elevate the price but also enhance the material’s suitability for unique applications.

Lead times also influence pricing. Urgent orders may incur premium charges, but planning ahead often results in more favourable rates. To better grasp the expense landscape, consider the following:

- The size of the order—smaller batches tend to be more costly per metre of diamond mesh steel.

- The degree of customisation—tailored designs and specialised finishes add to the overall cost.

- The lead time—expedited production and delivery often come with a financial premium.

Understanding these cost factors empowers you to make informed decisions, ensuring your investment in diamond mesh steel aligns perfectly with your project’s needs and budget constraints. When evaluating prices, always factor in the long-term durability and versatility that this material offers, turning a simple purchase into a strategic asset for your construction or industrial endeavour.

Installation and Maintenance Tips

Proper Installation Techniques

When it comes to installing diamond mesh steel, precision and patience are paramount. Proper installation not only maximises the longevity of the material but also ensures safety and aesthetic appeal. A meticulous approach begins with selecting the right tools—such as specialised clamps and welding equipment—to secure the diamond mesh steel effectively. Ensuring the mesh is taut and aligned correctly prevents future sagging or warping, which could compromise its structural integrity.

For optimal results, consider these installation tips: avoid over-tensioning the mesh, as this can lead to unwanted deformation, and always adhere to the manufacturer’s specifications for spacing and anchoring. If welding is part of the process, consistent heat application and clean joints are essential. Regular maintenance involves inspecting for signs of corrosion or damage and cleaning the surface with gentle detergents, especially if the diamond mesh steel has a protective coating. This upkeep preserves its resistance to environmental elements, extending the lifespan of your installation.

Cleaning and Maintenance Practices

Diamond mesh steel isn’t just a sturdy choice; it’s a testament to craftsmanship that endures the test of time and elements. Proper cleaning and maintenance breathe new life into this resilient material, ensuring it remains both functional and visually striking. Regular inspection is key—look for early signs of corrosion or damage that might threaten its integrity.

Cleaning practices should be gentle yet effective. Use soft brushes and mild detergents to remove dirt and grime without compromising the protective coatings. For those seeking to preserve the steel’s lustrous appearance, avoiding abrasive cleaners is essential. A well-maintained diamond mesh steel surface not only resists environmental wear but also retains its aesthetic appeal for years to come.

To streamline upkeep, consider implementing a simple routine:

- Inspect the mesh periodically for signs of corrosion or damage.

- Clean with a soft cloth or brush and a neutral cleaning solution.

- Apply a protective coating or sealant if necessary, to boost resistance against moisture and pollutants.

Remember, a little attention now can prevent costly repairs later. Ensuring your diamond mesh steel remains pristine is a dance of patience and precision, transforming utilitarian strength into an enduring symbol of resilience and beauty.

Troubleshooting Common Issues

Clear, seamless installation of diamond mesh steel is vital to prevent costly repairs down the line. Proper techniques can ensure maximum strength and longevity. When fixing the mesh, always verify that the support structure is stable and free of debris. Using appropriate fasteners and ensuring even tension helps maintain the integrity of the installation. If issues like sagging or loose fittings occur, addressing them promptly can save time and money.

Common troubleshooting problems include corrosion spots, which often result from inadequate protective coatings or exposure to harsh environments. Regular inspections can catch early signs of deterioration. If corrosion or damage appears, it’s advisable to clean the affected area thoroughly and consider applying a compatible protective coating or sealant. This adds an extra layer of defence against moisture and pollutants, prolonging the lifespan of your diamond mesh steel.

- Check the mesh for signs of rust or deformation.

- Ensure all fasteners are tight and correctly positioned.

- Replace damaged sections swiftly to maintain safety and durability.

By adhering to these simple steps, maintaining your diamond mesh steel becomes straightforward. Troubleshooting common issues quickly ensures your installation remains resilient and visually appealing for years to come. Remember, proactive care is the best way to extend the utility and beauty of your diamond mesh steel structure!

Environmental Impact and Sustainability

Eco-Friendly Manufacturing Options

In a world increasingly mindful of environmental stewardship, the production of diamond mesh steel stands as a testament to sustainable innovation. Modern manufacturing practices are evolving to minimise ecological footprints, ensuring that the beauty and strength of diamond mesh steel do not come at the expense of our planet. With eco-friendly options gaining momentum, manufacturers are adopting greener techniques that prioritise resource efficiency and waste reduction.

One notable approach involves using recycled steel in the manufacturing process, significantly reducing energy consumption and carbon emissions. Additionally, environmentally conscious coating techniques—such as powder coating—offer durable finishes without harmful solvents. For businesses seeking sustainable solutions, choosing suppliers that follow industry certifications and adhere to rigorous environmental standards can make all the difference. This commitment not only preserves the integrity of the environment but also enhances the longevity and resilience of diamond mesh steel, making it a truly sustainable choice for construction, fencing, and architectural designs.

- Recycled steel utilisation

- Low-VOC coating technologies

- Energy-efficient manufacturing processes

Recyclability of Diamond Mesh Steel

In an era where environmental consciousness shapes every industry decision, the ecological footprint of manufacturing processes becomes a critical consideration. Diamond mesh steel stands out not only for its structural robustness but also for its potential to be produced sustainably. The utilisation of recycled steel in manufacturing significantly diminishes energy consumption, reducing carbon emissions and conserving finite resources. This approach exemplifies how eco-friendly practices can coexist with industrial excellence.

Modern production of diamond mesh steel often incorporates low-VOC coating technologies, such as powder coating, which eliminate the need for harmful solvents. These environmentally conscious techniques enhance durability without compromising air quality. Moreover, energy-efficient manufacturing processes are increasingly adopted, harnessing innovations that minimise waste and optimise resource use. The result is a product that aligns with stringent environmental standards while maintaining superior quality and longevity.

Recyclability is another compelling aspect of diamond mesh steel. Its inherent ability to be remelted and repurposed ensures a circular lifecycle that supports sustainability initiatives. For businesses prioritising eco-friendly solutions, selecting suppliers committed to industry certifications and environmental standards can be transformative. Such practices not only uphold ecological integrity but also reinforce the enduring resilience of diamond mesh steel, making it a sustainable choice for diverse applications—from fencing and security to architectural accents.

Sustainable Use Cases

In an era where environmental impact influences purchasing decisions, the sustainability of diamond mesh steel becomes increasingly vital. Its recyclability ensures that the product can be remelted and repurposed repeatedly, supporting a circular economy. This characteristic not only reduces waste but also minimises the demand for virgin materials, conserving finite resources and lowering carbon emissions.

Furthermore, eco-conscious manufacturing practices are transforming the industry. Utilising low-VOC coatings like powder coating eliminates harmful solvents, improving air quality during production and application. Energy-efficient processes, combined with the use of recycled steel, mean that diamond mesh steel can meet rigorous environmental standards without sacrificing strength or durability.

For organisations committed to sustainability, choosing suppliers who adhere to recognised environmental certifications can make a significant difference. These diamonds in the rough offer versatile applications—from secure fencing and architectural accents to industrial enclosures—while supporting eco-friendly initiatives. The combination of recyclability and environmentally mindful production cements diamond mesh steel as a sustainable choice for a greener future.

Future Trends and Innovations

Technological Advancements

The future of diamond mesh steel is shimmering with promise, driven by rapid technological advancements that push the boundaries of strength and versatility. Innovations in manufacturing processes are enabling the production of custom patterns with unparalleled precision, opening new horizons for architects and engineers alike. Cutting-edge coating techniques, such as nanotechnology-based anti-corrosion layers, are increasing lifespan and reducing maintenance costs—further elevating diamond mesh steel’s appeal in demanding environments.

Emerging trends also include the integration of eco-friendly manufacturing options, making diamond mesh steel a sustainable choice for modern construction. Automating production through advanced robotic welding and weaving systems not only boosts efficiency but also enhances consistency across batches. A focus on recyclability and green practices ensures that diamond mesh steel remains aligned with global sustainability goals, promising a future where durability and environmental responsibility go hand in hand.

Emerging Applications

The future of diamond mesh steel is bright, driven by innovations that promise to redefine its role in modern construction and design. As technological advancements continue to push the boundaries of strength and versatility, we’re witnessing a shift towards smarter, more sustainable solutions. Cutting-edge manufacturing techniques are enabling the production of custom patterns with exceptional precision, catering to the specific needs of architects and engineers alike. This evolution not only enhances structural integrity but also opens up new possibilities for aesthetic and functional applications.

Emerging trends in diamond mesh steel include the integration of eco-friendly manufacturing practices. For instance, the adoption of green production processes and recyclable materials aligns with global sustainability goals. Additionally, automation through robotic welding and weaving systems is increasing efficiency and consistency, reducing waste and lowering costs. These innovations are making diamond mesh steel a more viable choice for complex projects that demand both durability and environmental responsibility.

With the rise of smart building concepts, applications for diamond mesh steel are expanding rapidly. From reinforced facades to innovative safety barriers, its adaptable nature makes it ideal for diverse environments. As the industry continues to evolve, expect to see even more specialised patterns and coatings—such as nanotechnology-based anti-corrosion layers—that extend lifespan and reduce maintenance. Clearly, the future of diamond mesh steel is not just about strength but about creating sustainable, smart solutions that stand the test of time.

Market Growth Forecasts

The future of diamond mesh steel is looking brighter than a freshly polished gemstone, with market growth forecasts projected to soar by over 8% annually in the next five years. This rapid expansion is driven by relentless innovations that push the boundaries of durability, sustainability, and design versatility. Industry insiders are buzzing about how emerging trends are transforming diamond mesh steel from a mere construction staple into a smart, eco-friendly marvel.

One of the most promising innovations is the integration of nanotechnology-based anti-corrosion coatings, which significantly extend the lifespan of diamond mesh steel. Coupled with advancements in automated manufacturing processes—such as robotic welding and precision weaving—the industry is witnessing a surge in custom patterns and environmentally conscious production methods. These developments not only optimise efficiency but also allow for complex, bespoke designs that meet modern architectural demands.

- Market analysts anticipate that the growing emphasis on sustainable building practices will fuel increased adoption of eco-friendly diamond mesh steel options, including recyclable materials and green production techniques.

- Furthermore, as smart building concepts become mainstream, applications for diamond mesh steel are expanding into innovative sectors like façade reinforcement, safety barriers, and even decorative elements.

With the global push for greener materials and smarter infrastructure, the trajectory for diamond mesh steel remains exceptionally promising. Its capacity to adapt to evolving standards and aesthetic preferences ensures that this versatile material will continue to be a key player in the future of construction and design. No wonder the market is forecasting a robust growth curve—diamond mesh steel isn’t just shining today; it’s set to dazzle for decades to come!