Understanding Diamond Mesh Material

Definition and Composition – What is diamond mesh material and what are its primary components?

Imagine a material so versatile it can turn a basic fence into a fortress or give a chic touch to a design project — that’s the magic of diamond mesh material! This innovative fabric is celebrated not just for its aesthetic appeal, but also for its impressive strength and durability. But what exactly makes up this marvel of modern engineering?

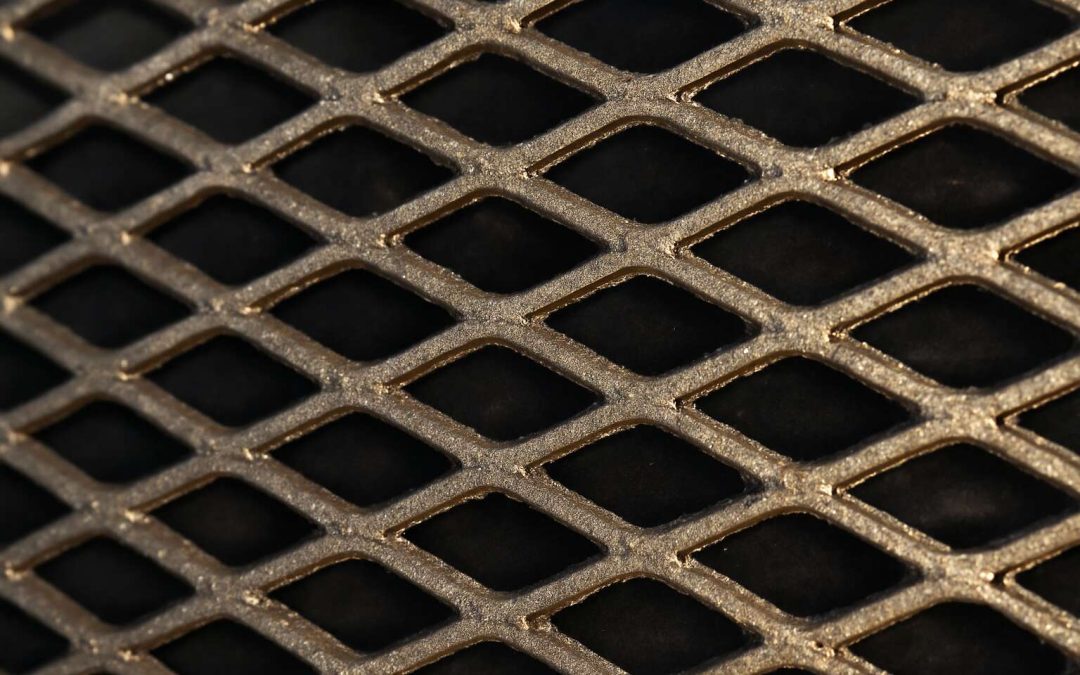

At its core, diamond mesh material is primarily composed of high-quality metals like stainless steel, aluminium, or even specialised plastics, depending on its intended use. The defining feature is its distinctive diamond-shaped pattern, which provides exceptional tensile strength while maintaining flexibility. This structure allows it to absorb impacts and resist wear far better than traditional mesh options. Interestingly, the primary components contribute to its resilience, corrosion resistance, and lightweight nature — making it an all-round star in both industrial and decorative applications.

- Metal wires or fibres — usually stainless steel, aluminium, or galvanised steel.

- Protective coating — such as zinc or polymer layers, enhancing longevity and resistance to environmental elements.

In essence, understanding the composition of diamond mesh material reveals why it’s the go-to choice for everything from security fencing to artistic installations. Its primary components are carefully selected to ensure it remains a reliable, long-lasting solution that combines strength with style.

Manufacturing Processes – How is diamond mesh material produced and fabricated?

Transforming raw metal into the intricate lattice of diamond mesh material is a craft that marries precision with artistry. The manufacturing process begins with selecting the highest quality metal wires—be it stainless steel, aluminium, or galvanised steel—each chosen for its unique properties. These wires are then meticulously shaped into the iconic diamond pattern, a process often achieved through a combination of advanced weaving or weaving-like techniques that ensure uniformity and strength.

To enhance durability and resistance to environmental elements, a protective coating—such as zinc or specialised polymer layers—is carefully applied. This layer not only prolongs the lifespan of the diamond mesh material but also preserves its aesthetic appeal even under harsh conditions. Sometimes, production involves a galvanisation process, where the metal is dipped into molten zinc, creating a formidable barrier against corrosion. This step is crucial for applications demanding long-lasting resilience, like security fencing or industrial enclosures.

Ultimately, the fabrication of diamond mesh material is an intricate dance of engineering and craftsmanship, transforming raw, elemental components into a versatile material that stands as a testament to modern manufacturing prowess. Its ability to combine strength, flexibility, and elegance makes it an unrivalled choice across diverse industries, from construction to artistic installation. Truly, the magic lies in the meticulous process of creation—each strand woven with purpose and precision.

Key Characteristics – Features that make diamond mesh material unique and desirable

In the realm of construction, security, and artistic expression, few materials boast the versatility and resilience of diamond mesh material. Its unique geometric pattern isn’t just eye-catching; it’s engineered for strength, making it a favourite among architects and manufacturers alike. What truly sets it apart is the way it marries durability with flexibility—imagine a material that can withstand the rigours of industrial environments while maintaining an elegant, almost delicate appearance.

One of the standout features of diamond mesh material is its exceptional resistance to corrosion and environmental wear. Whether galvanised for maximum longevity or coated with specialised polymers, this material adapts seamlessly to harsh conditions. Its lightweight nature, combined with high tensile strength, makes installation a breeze—no heavy lifting required, yet it holds firm against forces that would challenge lesser materials.

Moreover, diamond mesh material is highly customisable. It can be fashioned into various sizes and shapes, and its open lattice design allows for excellent airflow and visibility. This makes it ideal not just for fencing but also for artistic installations, filtration systems, and security screens. Its design flexibility means it can be tailored to meet the specific demands of diverse industries, from agriculture to aerospace. Truly, this material’s adaptability is what keeps it in the spotlight as a top-tier choice for innovative projects across sectors.

Applications of Diamond Mesh Material

Industrial Uses – Applications in construction, fencing, and industrial safety

In the realm of modern industry, few materials conjure a sense of resilience and versatility quite like diamond mesh material. Its formidable strength and adaptability make it an indispensable component across a multitude of applications. For instance, in construction, it acts as a robust reinforcement, stabilising structures and preventing debris from escaping, ensuring safety and compliance with stringent standards.

Fencing, too, benefits immensely from the unique properties of diamond mesh material. Its intricate pattern provides a formidable barrier against intruders while allowing visibility and airflow—a perfect blend of security and practicality. In industrial safety, this material proves vital in creating secure work environments, safeguarding personnel without sacrificing ventilation or ease of access.

The widespread adoption of diamond mesh material illustrates its unparalleled capacity to combine durability with flexibility, transforming the way industries approach safety and security. Whether used in high-stakes construction projects or protective enclosures, this material’s strength and resilience continue to set new standards in industrial applications.

Architectural and Design – Use in interior design, decorative panels, and architectural lacing

In the world of architecture and design, where aesthetics coalesce with function, diamond mesh material emerges as a marvel of modern ingenuity. Its geometric elegance transforms ordinary spaces into captivating visual expressions, offering a harmonious dance between form and practicality. Used as decorative panels, diamond mesh material lends an air of sophistication — revealing glimpses of the interior while maintaining an aura of mystery and allure.

Architects and interior designers cherish its versatility, often employing diamond mesh material as architectural lacing that weaves transparency with strength. It can serve as a stunning room divider, a bespoke ceiling feature, or an artistic façade that catches the light with every movement. The intricate diamond pattern infuses spaces with texture, depth, and personality, making it a preferred choice for modern, innovative environments.

- Decorative wall panels that create visual interest and texture.

- Feature ceilings that bounce light and cast dramatic shadows.

- Customisable partitions that define spaces without sacrificing openness.

With its inherent ability to blend durability with design flair, diamond mesh material stands as a testament to the seamless marriage of artistry and engineering. Its unique properties unlock endless possibilities, elevating architectural concepts into realms of the extraordinary. Truly, this material invites a dialogue between space and viewer — a visual symphony in every crafted detail.

Agricultural and Environmental – Utilization in fencing, netting, and erosion control

In the realm of agricultural and environmental solutions, diamond mesh material’s resilience and versatility are nothing short of revolutionary. Its robust yet lightweight structure makes it an ideal choice for fencing that withstands the harshest weather conditions and animal pressure alike. Farmers and environmentalists alike turn to this material to create reliable barriers that protect crops, livestock, and sensitive ecosystems.

One of the most compelling applications of diamond mesh material lies in erosion control. Its unique diamond pattern provides excellent stability, allowing it to be used as a protective layer on slopes or along riverbanks. The interwoven design effectively dissipates the force of flowing water and shifting soil, reducing erosion and preserving the landscape. For large-scale projects, its durability and flexibility make it indispensable.

Moreover, the adaptability of diamond mesh material extends to a variety of environmental uses, including:

- Fencing for wildlife conservation areas

- Netting for crop protection and bird deterrence

- Erosion barriers on vulnerable terrains

Its capacity to blend strength with environmental sensitivity cements diamond mesh material as a cornerstone of sustainable land management. Whether used to contain livestock, safeguard plants, or stabilise fragile earth, this material’s strategic implementation offers a seamless marriage of form and function—an unassuming hero in the ongoing quest for ecological balance.

Advantages of Diamond Mesh Material

Strength and Durability – How diamond mesh withstands wear and tear

In the realm of industrial innovation, few materials evoke such admiration for their resilience as diamond mesh material. Its remarkable strength and durability are not mere happenstances but the result of meticulous engineering that harnesses the inherent toughness of its composition. When subjected to the relentless wear and tear of demanding environments, diamond mesh material consistently defies degradation, maintaining structural integrity over extended periods.

This resilience is rooted in its unique fabrication process, which ensures a dense, interlocking pattern capable of absorbing shocks and resisting corrosion. The interwoven metallic strands forge an almost impenetrable barrier, making it an ideal choice for applications where longevity is paramount. For industries seeking a dependable, high-performance solution, the durability of diamond mesh material translates into reduced maintenance costs and prolonged service life. Its capacity to withstand the rigours of environmental and mechanical stress underscores its position as an indispensable component across diverse sectors.

Lightweight and Flexibility – Benefits for ease of installation and versatility

When it comes to versatile construction materials, lightweight yet robust options are often the most sought after. Diamond mesh material shines in this regard, offering an exceptional combination of strength and flexibility. Its delicate appearance belies an underlying resilience, making installation simpler and more efficient. This flexibility allows for easy adaptation to various shapes and surfaces, which is particularly advantageous in architectural and design projects.

The inherent lightness of diamond mesh material reduces the load on supporting structures, translating into significant savings in transportation and labour costs. For those seeking a high-performance, adaptable solution, the benefits are clear. Its malleability is especially valuable in applications such as decorative panels or safety barriers, where customised fitting matters.

- Ease of handling during installation

- Compatibility with diverse architectural styles

- Reduced structural load

In essence, the lightweight and flexible nature of diamond mesh material not only enhances its usability but also broadens the scope for innovative design and efficient construction. It’s a true testament to how advanced materials can meet the practical demands of industries while maintaining an elegant, functional form. This blend of characteristics makes diamond mesh material a preferred choice across multiple sectors, underpinning projects with both durability and aesthetic appeal.

Corrosion Resistance – Benefits of rust-proof and weather-resistant properties

In an era where environmental resilience is no longer a luxury but a necessity, the corrosion resistance of diamond mesh material becomes a paramount attribute. Its inherent ability to withstand the relentless assault of rust and weathering elevates its status from a mere construction component to an enduring symbol of robustness. Unlike conventional metals, this material is crafted with protective coatings or corrosion-resistant alloys that fortify it against moisture, salinity, and temperature fluctuations, ensuring longevity even in the harshest environments.

This resilience translates into tangible advantages—reduced maintenance, fewer replacements, and sustained aesthetic appeal. When subjected to the elements, diamond mesh material remains pristine, upholding its structural integrity without succumbing to oxidation or decay. For industries seeking a durable yet elegant solution, its weather-resistant properties are indispensable. Moreover, its rust-proof nature makes it ideal for outdoor fencing, architectural facades, and environmental applications where exposure to moisture is inevitable.

Embracing the advantages of corrosion resistance in diamond mesh material means investing in a product that seamlessly marries function with form, standing resilient through time’s unyielding march. Its ability to resist rust and weather-related deterioration redefines durability, making it a superior choice for diverse applications—from industrial safety barriers to sophisticated architectural designs, where resilience is non-negotiable.

Aesthetic Appeal – Visual benefits and customization options

In a world where aesthetics and durability dance in perfect harmony, the beauty of diamond mesh material shines with undeniable allure. Its distinctive diamond-shaped pattern creates a visual rhythm that captivates the eye, transforming utilitarian structures into striking architectural statements. The intricate lattice work lends an air of sophistication, elevating the simplest fence or panel into a work of art. This material’s versatility allows for endless customization — from sleek, modern finishes to ornate, decorative effects—making it a favourite among designers and architects alike.

Furthermore, diamond mesh material offers a palette of options to suit any vision. Whether you desire a subtle metallic sheen or a bold colour accent, its adaptable surface can be tailored to your aesthetic needs. The ability to incorporate various coatings and finishes ensures that each installation is as unique as the environment it inhabits. This seamless blend of form and function makes diamond mesh material not only a resilient choice but also an expression of creative elegance.

Types and Variations of Diamond Mesh Material

Material Types – Steel, stainless steel, plastic, aluminum, and other variants

Within the realm of industrial craftsmanship, the variety of diamond mesh material available is as expansive as a mystical forest teeming with life. Each type bears its own unique traits, suited to specific needs and environments. From the gleaming resilience of steel to the corrosion-resistant elegance of stainless steel, these materials transform utilitarian grids into works of durable art. Plastic variants, often lightweight and versatile, lend themselves perfectly to temporary or decorative applications, while aluminium offers a harmonious balance of strength and weight — ideal for projects demanding both resilience and ease of handling.

For specialised uses, manufacturers have developed other variants that push the boundaries of traditional diamond mesh material. Some incorporate galvanised coatings for enhanced rust resistance, while others are reinforced with composite layers for added strength. The choice of material hinges on factors such as environmental exposure, load-bearing capacity, and aesthetic goals. In the enchanted landscape of modern construction and design, these variants of diamond mesh material serve as the backbone of safety, style, and sustainability.

Mesh Weaves and Patterns – Different mesh sizes, open areas, and weave styles

In the labyrinthine world of industrial design, the subtle intricacies of diamond mesh material reveal a tapestry of possibilities as vast as a forest of shimmering leaves. Each variation in weave style and pattern unlocks a new dimension of utility and aesthetic appeal, transforming utilitarian grids into expressions of craftsmanship and resilience. The diversity of mesh sizes and open areas allows architects and engineers to tailor their creations precisely, balancing strength and transparency with tailored finesse.

Among the myriad options, the weave styles of diamond mesh material can be categorised into distinct patterns, each offering unique advantages. For instance, the classic criss-cross weave provides a balanced blend of durability and flexibility, while specialised variants incorporate adjustable mesh sizes to meet precise load-bearing or ventilation needs.

- Mesh openings ranging from fine to broad

- Varied diamond shapes and angles

- Enhanced patterns for decorative or structural purposes

These variations foster a symphony of functional aesthetics, serving both the pragmatic and the artistic realms of construction and design.

Moreover, the specific pattern of diamond mesh material influences its performance and visual impact. Smaller mesh sizes, with their denser open areas, excel in security applications and fine filtration, whereas larger meshes facilitate airflow and light diffusion in architectural installations. The intricate dance between open area and mesh size underscores the material’s versatility—each choice a deliberate act of balancing strength, transparency, and visual harmony.

Coatings and Finishes – Galvanized, powder-coated, and corrosion-resistant coatings

In the shadowed corridors of industrial innovation, the true character of diamond mesh material is revealed not solely in its woven patterns but in the enigmatic coatings that adorn it. The coatings serve as a silent guardian, transforming a simple mesh into a resilient fortress against the ravages of time and weather. Galvanised finishes, for instance, lend a formidable rust-proof barrier, preserving the integrity of the material amidst the relentless assault of moisture and corrosion.

Equally compelling is the world of powder coating—an artful blend of colour and protection that grants the diamond mesh material a customised aesthetic while fortifying it against environmental decay. For applications demanding heightened resistance, specialised corrosion-resistant coatings create an almost impenetrable shield, ensuring longevity in the harshest of environments. These finishes do more than protect; they elevate the visual allure of the material, whispering promises of durability wrapped in elegance.

- Galvanised coatings — the stalwart guardians against rust and decay.

- Powder-coated finishes — vibrant hues combined with weather-resistant strength.

- Specialised corrosion-resistant layers — designed for the most unforgiving landscapes.

Each variation in coating and finish breathes new life into the humble diamond mesh material, transforming it into an artefact of resilience and aesthetic mastery—an element that whispers the tales of craftsmanship woven into its very core.

Choosing the Right Diamond Mesh Material

Factors to Consider – Application requirements, environmental conditions, budget

Choosing the right diamond mesh material requires careful consideration of several critical factors to ensure it meets your specific needs. Application requirements are paramount; whether you need a robust fencing solution or a decorative panel, understanding the intended use guides the selection process. For instance, industrial safety applications demand high strength and durability, while architectural projects might prioritise aesthetic appeal and finish.

Environmental conditions also play a vital role. If the diamond mesh material will be exposed to harsh weather or corrosive environments, opting for options with superior corrosion resistance, such as galvanised or powder-coated finishes, becomes essential. Budget constraints should not be overlooked—there are diverse material types, from lightweight aluminium to sturdy stainless steel, each fitting different price points and performance levels.

Ultimately, balancing application needs, environmental factors, and budget allows for optimal selection of the perfect diamond mesh material, ensuring longevity and functionality in every project.

Sizing and Dimensions – Selecting the appropriate mesh size and wire gauge

Choosing the right diamond mesh material hinges on selecting the appropriate sizing and dimensions to match your project’s specific needs. The mesh size and wire gauge directly influence the strength, flexibility, and visual appeal of the final product. A finer wire gauge with smaller openings offers a delicate, decorative look, perfect for architectural panels or interior accents. Conversely, larger openings and thicker wires are designed for heavy-duty fencing or industrial safety applications where durability is paramount.

Understanding the various options available is crucial. For example, you might consider:

- Mesh sizes ranging from minimal (for intricate decorative work) to expansive (for fencing and security)

- Wire gauges that vary from lightweight aluminium to robust stainless steel

Matching these dimensions with environmental conditions and application demands ensures optimal performance. Whether the goal is resilience against corrosion or ease of installation, the sizing choices for your diamond mesh material will determine both functionality and aesthetic impact. When selecting, always keep in mind that the right combination can elevate a simple design into a striking feature, or reinforce safety and protection in demanding environments.

Supplier and Quality Assurance – How to verify quality and source from reputable suppliers

Choosing a reliable supplier for your diamond mesh material is essential for ensuring quality and durability. With the market flooded with options, verifying a supplier’s reputation becomes a top priority. Look for suppliers who provide transparent information about their manufacturing processes and material origins. Reputable companies often carry certifications that guarantee adherence to strict quality standards.

To help you assess potential suppliers, consider this list:

- Request samples to evaluate the quality of the diamond mesh material.

- Check for customer reviews and testimonials to gauge reliability and service.

- Ask about available coatings and finishes, such as galvanised or powder-coated options, to match your environmental needs.

- Verify lead times and after-sales support to ensure smooth project execution.

Sourcing from a trusted supplier guarantees that your diamond mesh material will meet your specifications, whether for industrial fencing, architectural features, or environmental applications. Quality assurance isn’t just a checkbox — it’s the foundation of a successful project.

Maintenance and Care for Diamond Mesh Material

Cleaning Techniques – Best practices for keeping the material in optimal condition

Maintaining the pristine allure of diamond mesh material requires a nuanced approach, as its durability is matched only by its susceptibility to environmental factors. A careful maintenance routine ensures that its unique weave and aesthetic appeal remain uncompromised over time. Regular cleaning not only preserves its visual splendour but also extends its lifespan, making it a wise investment for both industrial and decorative applications.

Cleaning techniques for diamond mesh material should be gentle yet effective. Using a soft brush or cloth combined with mild soap and water usually suffices to remove dirt and grime. For more stubborn stains or accumulated pollutants, a diluted mixture of vinegar and water can be employed, ensuring the integrity of the coating and finish. It’s crucial to avoid harsh chemicals or abrasive scrubbers that could damage the surface or disturb the weave pattern.

To keep the diamond mesh material in peak condition, routine inspections are recommended. Check for signs of corrosion, especially if the mesh is exposed to outdoor elements. If rust or corrosion begins to form, applying a specialised protective coating or galvanised treatment can prevent further deterioration. Ultimately, consistent care enhances both the resilience and visual appeal of this versatile material.

- Regularly remove debris and dirt using a soft brush or cloth.

- Use mild cleaning solutions like soap and water, avoiding abrasive agents.

- Inspect for corrosion or damage, especially in exposed environments.

- Apply protective coatings or treatments if necessary to prolong durability.

Repair and Replacement – Signs of damage and how to address wear over time

Over time, even the most resilient diamond mesh material reveals its secrets—signs of wear whisper their warnings through rust spots, bent wires, or frayed edges. These subtle marks are often the first indication that the integrity of the mesh is compromised, threatening both its aesthetic allure and structural strength. When damage appears, prompt intervention can stave off further deterioration, safeguarding your investment against the relentless march of environmental decay.

Addressing damage requires a keen eye and a measured approach. Minor issues such as loose or bent wires can often be corrected with specialised repair techniques, restoring the mesh’s original form. For more severe degradation, replacement of affected sections may be necessary.

- Inspect regularly for corrosion, especially in outdoor settings.

- Remove any rust with a wire brush designed for metal surfaces.

- Apply a protective coating or galvanised treatment post-repair to bolster resilience.

These steps help preserve the integrity and visual appeal of your diamond mesh material, ensuring it endures long after the initial installation.

Longevity Tips – Ensuring durability and prolonging lifespan

Maintaining diamond mesh material isn’t just about aesthetics; it’s about ensuring longevity and functionality. Regular inspections are crucial. Look out for rust spots, bent wires, or frayed edges, as these are early signs that your mesh might be nearing the end of its lifespan. Addressing minor issues promptly can prevent costly replacements later on.

Cleaning is straightforward but must be consistent. Using a wire brush designed for metal surfaces helps remove surface rust and debris. After cleaning, applying a protective coating or opting for galvanised treatments can significantly enhance resistance to environmental elements—especially in outdoor settings where corrosion is a constant threat.

For those keen on preserving their investment, a simple maintenance routine can go a long way.

- Regular visual inspections

- Prompt repair of minor damage

- Consistent cleaning and coating application

These steps are key to prolonging the lifespan of your diamond mesh material, ensuring it remains resilient and visually appealing over time. When properly cared for, this versatile material continues to serve effectively in fencing, industrial applications, and decorative projects alike.

Environmental Impact and Sustainability

Eco-Friendly Manufacturing – Sustainable production practices for diamond mesh

Amid growing environmental concerns, the push for sustainable manufacturing practices in the production of diamond mesh material has never been more critical. Manufacturers are increasingly adopting eco-friendly methods that minimise ecological footprints, ensuring that the creation of this versatile material aligns with global sustainability goals. The process now often involves the utilisation of recycled metals and environmentally conscious coatings, significantly reducing harmful emissions and waste.

Eco-friendly manufacturing of diamond mesh material isn’t merely a trend but a necessity. By prioritising sustainable production practices, companies can reduce energy consumption and promote responsible resource management. Innovations such as galvanised coatings that extend lifespan without hazardous chemicals are transforming the industry. Additionally, some suppliers implement closed-loop systems, recycling scrap and wastewater, which enhances the overall eco-efficiency of diamond mesh material production.

- Use of recycled raw materials

- Low-impact, non-toxic coatings

- Energy-efficient fabrication techniques

- Waste minimisation and recycling programs

As environmental impact remains at the forefront of industrial innovation, the sustainable production practices of diamond mesh material exemplify how responsible manufacturing can harmonise durability with ecological integrity. This approach not only safeguards our planet but also assures quality and longevity for end-users, making it a compelling choice for environmentally conscious projects.

Recyclability – Recycling options and environmental benefits

In an era where ecological stewardship is paramount, the environmental impact of manufacturing processes must be scrutinised. Diamond mesh material stands at the forefront of sustainable innovation, embodying a commitment to recyclability and environmental benefits. Its production increasingly relies on recycled raw materials, reducing reliance on virgin metals and conserving natural resources. This shift not only diminishes the carbon footprint but also champions responsible manufacturing practices.

Recycling options for diamond mesh material are both diverse and effective. Many suppliers now offer products fabricated from recycled steel or aluminium, ensuring a closed-loop lifecycle. The environmental benefits of such practices are profound—minimising waste, lowering energy consumption, and curbing greenhouse gas emissions. Moreover, eco-friendly coatings, such as non-toxic powder finishes or galvanised layers, extend the lifespan of the material without hazardous chemicals, promoting durability alongside sustainability.

To optimise the eco-efficiency of diamond mesh material, some manufacturers implement comprehensive recycling programs. These include reprocessing scrap metal and wastewater, significantly reducing waste and conserving water. Implementing these sustainable measures not only preserves our planet but also guarantees a high-quality, long-lasting product that aligns with modern environmental standards.

Life Cycle Considerations – Durability versus environmental footprint

In a world increasingly driven by sustainable innovation, the environmental impact of construction and industrial materials cannot be overlooked. Diamond mesh material exemplifies a progressive approach, balancing durability with ecological responsibility. Its lifecycle considerations reveal a nuanced interplay between longevity and environmental footprint. While it boasts impressive resilience—resisting corrosion, wear, and tear—its production and recycling processes are designed to minimise ecological harm. This thoughtful design ensures that the environmental costs of manufacturing are offset by the material’s ability to be recycled and reused multiple times, embodying a true commitment to eco-friendly practices.

When considering the sustainability lifecycle of diamond mesh material, durability does not have to come at the expense of environmental consciousness. Many suppliers now utilise recycled steel and aluminium, fostering a closed-loop manufacturing cycle. This approach significantly reduces the reliance on virgin raw materials, limiting the depletion of natural resources. Additionally, eco-friendly coatings such as galvanised finishes or powder coatings extend the lifespan of the mesh while avoiding hazardous chemicals. The result is a product that offers high-performance resilience, with a markedly reduced ecological footprint over its service life.

- Recycling scrap metal

- Reprocessing wastewater

- Applying non-toxic, corrosion-resistant coatings

These practices exemplify how sustainable manufacturing can harmonise with industrial demands. The ongoing debate between durability and environmental impact often centres on whether long-lasting materials inherently generate more waste. However, diamond mesh material demonstrates that strategic design and responsible production can achieve both: a durable, reliable product that also champions environmental stewardship. As technology advances, the focus on reducing ecological footprints without compromising quality continues to shape the future of diamond mesh material, offering a compelling example of sustainable innovation in the industrial landscape.